Heavy Equipment Maintenance Checklist

Daily maintenance will help you avoid costly repairs and downtime for your heavy machinery. Preventative maintenance (PM) and regular tests with competent operators will significantly reduce costs. The owner’s manual contains these checklists and schedules.

What To Check For

Listening to the operators is the first step. When something is wrong with their machine, they can usually feel it. Operators should be taught to search their computers for the fundamentals before using them. Operators who are well-versed in their machines know a lot more about how to use them. They will alert the technicians to minor issues before they turn into expensive repairs.

Begin the inspection on the ground, checking lights, steps, the undercarriage, hydraulic lines, electrical wires, fuel, and DEF tanks, and making sure the machine is greased, among other things. Proceed from the bucket to the boom, pins and bushings, hydraulic system, and other fluids from there. Operators can and should perform daily checks.

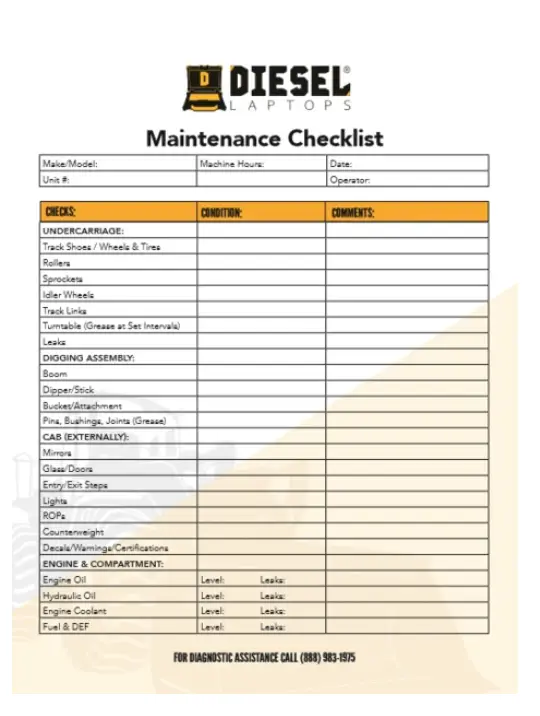

CLICK IMAGE TO DOWNLOAD THE MAINTENANCE CHECKLIST

It is important to follow the instructions outlined in your manual’s maintenance portion during PM time and to follow the manufacturers’ recommended service intervals at a minimum. Keep in mind that the manuals typically do not consider the severe use conditions under which equipment is often used. If your machine is new enough, you’ll most likely be covered by a warranty and will need to maintain these records.

Making Needed Repairs

Regardless of how much maintenance you do, an issue will inevitably occur. To diagnose these issues, you’ll need a qualified technician and some software. For dealer-level diagnostic tools, click here.